The Robert W. Plaster Free Enterprise and Research Center Innovation Studio 3D Print Lab is an exciting space equipped with high quality 3D printing and other equipment.

Reserve the Lab

3D Print Lab FAQ

How do you order a print?

Please email your file to bkanoy@umkc.edu along with any instructions, quantity, or sizing information. Print Lab personnel will prepare a quote for you. For accounting purposes, a quote is required prior to any 3D printing.

How much does 3D printing cost?

3D print charges are based on several factors including printing process, (which kind of printer is used) material and support material usage, and customer classification. Per volume, FDM is cheapest, costing a few dollars per cubic inch. Polyjet is more expensive and is charged at cents per gram of resin used. Metal printing is very expensive, and each project is individually priced, typically in the neighborhood of dollars per gram. You may obtain a customized quote by emailing bkanoy@umkc.edu.

How long does 3D printing take?

Many factors influence print times. Size and complexity, material used, and amount of support required directly affect cost. It is important to note that due to the possibility of print failure, print finish times are never guaranteed. Your quote will include the anticipated print length, for reference only. Some considerations, all proceeded with the statement “In general. . .”

Polyjet is the fastest type of printing, FDM next, then Metal.

Flatter objects print faster, dimension (height) is the most costly dimension in terms of time.

Lower infill density usually makes a good part and is much faster.

Doubling the size of an object increases the volume eight-fold.

How does one become an authorized user of the F170 printers in P104?

If you are a senior in the ME, EE, or CE program, you will be granted access to P104 and the printers upon completion of 3D printer training. Otherwise contact Dr. Katherine Bloemker or the Fabrication Studio Manager to arrange access and schedule prerequisite training..

3D Printing Equipment List

- 2ea. Stratasys F170 Fused Deposition Modeling 3D printers (Located in P104)

- 2 ea. Stratasys F370 Fused Deposition Modeling 3D printers (Located in P202)

- 2 ea. Stratasys Polyjet 826 Resin 3D printers (Located in P202)

- 1 ea. Rapidshape I50+ DLP Resin 3D printer

- 1 ea. Kurtz Ersa Alpha 140 Powder Bed Metal Laser (Located in P202)

The lab currently operates two Stratasys F170 Fused Deposition Modeling printers, located in Plaster Center P104. These printers are available for authorized students to use anytime. Typically,PLA and ABS are the materials available to print on these machines.

The lab itself, located at Plaster Center P202, contains two Stratasys F370 FDM printers which are typically set up for ABS and ABS-CF10 (carbon fiber reinforced ABS)as well as well as a StratasysFortus 450 MC printer that is typically set up to print Nylon 12CF (carbon fiber reinforced Nylon 12.)

The lab also contains two Polyjet J826 Resin printers. These machines can print extremely detailed models using a selection of materials that can be mixed to provide different colors and material properties.

The lab contains a Kurtz Ersa Alpha 140 Powder Bed Metal Laser printing system. This machine can make small metal parts from 314 Stainless steel and other materials, that are usable without further sintering.

These are the most popular pieces at the 3D Printing Studio. For a a list of all of the equipment available, read the full equipment list.

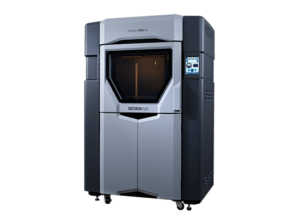

Fused Deposition Modeling Printer

Manufacturer: Stratasys

Model: F-170

Fused Deposition Modeling Printer

Manufacturer: Stratasys

Model: F-370

Polyjet Printer

Manufacturer: Stratasys

Model: Polyjet J826

Fused Deposition Modeling Printer

Manufacturer: Stratasys

Model: Fortus 450MC

Accessories: Engineering Materials, Reinforced Nylon

Composite FDM Printer

Manufacturer: Markforged

Model: X-7

Accessories: Continuous fiber reinforcement capable

Metal Powder Bed Printer

Manufacturer: Kurtz Ersa

Model: Alpha 140

DLP Resin Printer

Manufacturer: Rapidshape

Model: 150

Vacuum Former

Manufacturer: Formech

Model: 450DT

Laser Engraver

Manufacturer: Epilog

Model: Fusion Pro 48